Mechanical Products

Heating & Pumping Unit

Heating & Pumping Unit are used to preheat the fuel oil to the required firing temperature about 110 °C for furnace oil having redwood viscosity 1500 cst at 100 °F. In some cases they are used as”booster heater” to bring the temperature of oil firing level which was earlier cooled down due topipeline losses.The heater may consist of one or more tubular.

OIL LINE PREHEATERS

Oil line preheaters can be flanged in the line to heat Furnace oilup to 50°C to reduce its viscosity and facilitate easy flow in thepipeline.In some cases they are used as “booster heater” tobring the temperature of oil to firing level which was earlier cooled down due to pipeline losses.We manufacture heatersin vertical or horizontal mounting design.

TANK OUTFLOW HEATERS

Tank outflow heaters can be directly welded to the service / Daytank so that the Furnace oil coming out of the tank gets heatedinstantly and reduces the load on the motor in the heating unitinstalled further. Renewable cartridge type heating elements canbe replaced without emptying the oil tank, as the heater is not indirect contact with the oil.

THERMIC FLUID CIRCULATING SYSTEM

Thermic fluids are used for high temperature (maximum up to 300° C), high volumetric circulation. They constitute low surface load oil preheaters with renewable cartridge type heating elements, thermostats / RTD sensor / PT 100 / digital controllers and special high discharge capacity screw gear pumps/centrifugal pumps, driven by suitable electric motor. Applications are in systems which require heat transfer from a fluid, such as Paper Lamination, Roller Annealing, Plastic Extrusion, etc.

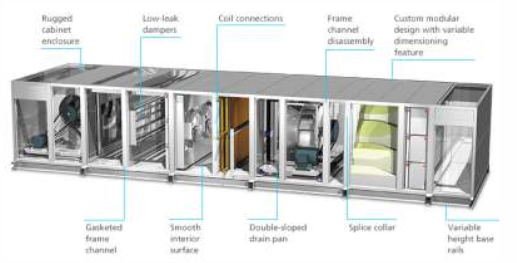

AHU (Air Handling Unit)

Air handling unit, or AHU, is a piece of HVAC equipment that is designed to regulate and circulate air throughout a space. Air handlers typically connect to a duct work ventilation system that distributes the conditioned air throughout the building and returns it back to the unit.The capacity of an air handler is most commonly measured by the amount of air it conditions and distributes.This measurement is calculated in volumetric units known as CFM.

The AHU is used to control the following parameters of the space

- Temperature

- Humidity

- Air Movement

- Air Cleanliness

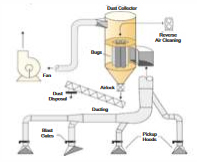

DUST COLLECTORS

The Dust collection system is used in industries where the working includes dust generating application. This machines are developed with high suction capacities that makes it suitable for wet and dry dust generating applications.The system efficiently clean the environmental air by collecting dust.

Customize dust - collector

Cyclone dust - collector

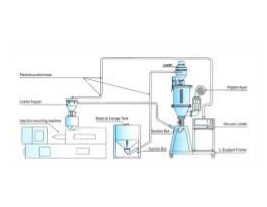

HOPPER LOADER

Microprocessor programmed operation; Alarm for shortage of material; Adopted high-speed motor, small volume with strong suction power, suitable for deferent type of new materials; installed withdust collector to save dismantling mainframe for cleaning; Remote controller, easy to set andcontrol, convenient and fast; Installed with air filter (options available).

OIL LINE PREHEATERS

TANK OUTFLOW HEATERS

THERMIC FLUID CIRCULATING SYSTEM

BLOWERS

Centrifugal Blower

Centrifugal fans include products with many different blade configurations.Examples include forwardcurve, backward curve, air foil, backward incline and radial tip.With centrifugal fans, the fan bladerotates perpendicular to the air flow. Centrifugal blowers use high-speed impellers or blades to impartvelocity to air or other gases.We as a company manufacture all types of Blowers.

Turbine Blower

Centrifugal fans include products with many different blade configurations.Examples include forwardcurve, backward curve, air foil, backward incline and radial tip.With centrifugal fans, the fan bladerotates perpendicular to the air flow. Centrifugal blowers use high-speed impellers or blades to impartvelocity to air or other gases.We as a company manufacture all types of Blowers.

AXIAL FAN

An axial fan is a type of fan that causes gas to flow through it in an axial direction, parallel to theshaft about which the blades rotate.The flow is axial at entry and exit.The fan is designed toproduce a pressure difference, and hence force, to cause a flow through the fan.Factors whichdetermine the performance of the fan include the number and shape of the blades. Fans have manyapplications including in wind tunnels and cooling towers.Design parameters include power, flowrate, pressure rise.

IMPELLER

The main part of a centrifugal compressor is the impeller.An open impeller has no cover, thereforeit can work at higher speeds. A compressor with a covered impeller can have more stages than onethat has an open impeller.There are two types of impellers, depending on the flow regime created.

Stainless Steel Impeller

Mild Steel Impeller

INDUSTRIAL ROLLERS

Our product range includes custom/standard made industrial rubber/metal rollers, Ceramic rollers,which are used in packaging industries, textile industry, paper industry, steel industry, tire industryand plywood industry and many others.